Welcome to Misha Petrochemicals Limited

Welcome to Misha Petrochemicals Limited

About Us

Welcome to Misha Petrochemicals Limited!

Reliability, Capability, and Excellence – Misha Petrochemicals stands on these pillars. Established in 2020, we hold a strong position as a Polymers and Flexible Packaging Films trading company, serving Industrial Packaging, Automotive, FMCG, Construction, Textile, and many more industries.

Our decades of industry experience and an extensive global network allow us to quickly and effectively identify and meet your specific needs.

We take the responsibility to use recyclable packaging materials and do everything we can to address our clients’ environmental concerns.

- FCMG

- Textiles

- Industrial Packaging

- Construction

- Automotive

- Agriculture

Vision

- To create a globally admired brand that excels as a leader in the polymer industry.

Mission

- Invest in a highly skilled workforce, establish a robust supply chain, and implement a sound marketing strategy that communicates the unique value propositions of the brand.

What We Offer?

- Quality is at the forefront of all products manufactured by our diverse suppliers.

- Our dedicated teams specialize in various product lines, bringing over 38 years of experience in the Polymer industry.

- To optimize lead times, our distribution channels span the country.

- Our highly transparent professional approach aims to develop mutually beneficial and long-lasting business relationships.

Core Values

INTEGRITY

ETHICAL BEHAVIOUR

TRANSPARENCY

COMMITMENT

RESPONSIBILITY

TEAM WORK

THINKING BIG

Our Products

PP (Polypropylene)

Polypropylene (PP) is lightweight, durable, and resistant to moisture, heat, and chemicals. It has a melting point of 130°C. It is used in the packaging of consumer products and plastic parts of many industries like automotive, etc.

PP Homopolymer Rafia Grade

This polypropylene plastic is durable, resistant to puncturing and tearing, and possesses a high melting point. It is used in sacks, woven bags, and packaging materials. This effective and affordable plastic is an alternative to cotton, jute, and paper.

PP Impact Copolymer

It is synthesized by copolymerizing propylene with a small amount of ethylene or butene. The resulting material is excellent to be used in applications requiring high resistance to stress and impact. PP Impact Copolymer is suitable for making parts for appliances, cars, and other industrial applications where toughness and durability are important.

PP Homopolymer Film Grade

Famous for its perfect clarity and gloss, PP homopolymer film grade is used in medical packaging, food packaging, and protective coatings. Its high melting point and low melt flow rate make it suitable to be processed into tough and strong films.

PP Homopolymer Injection Molding Grade

Suitable for injection molding processes, this high-density polymer is used to manufacture medical appliances, packaging, automotive, etc. It is popular for its low-cost, stiffness, and chemical-resistant properties.

PP Homopolymer Lamination Grade

Characterized by a low melt flow rate and high melting point, PP homopolymer lamination grade combines paper and aluminum foil to produce laminated films with strong barrier properties. It is manufactured based on the thickness required for specific applications.

PP Random Copolymer

This polypropylene is obtained by the polymerization of propylene and a smaller proportion of ethylene or butene. Due to the random distribution of butene or ethylene along its polymer chain, the resulting copolymer is more flexible, transparent, and impact resistant. It is used in automotive parts, food packaging, and household goods.

PVC Resin K-value 57

PVC Resin K-value 57 is softer and more flexible than K-value 67. Thus, electrical cables, medical tubing, inflatable products, and packaging materials are made from it. This type can be easily processed by various methods, such as extrusion, injection molding, and blow molding.

PVC (Polyvinyl Chloride)

Polyvinyl Chloride (PVC) is durable, affordable, and resistant to weather effects and chemical corrosion. This synthetic plastic polymer is mainly used in pipes, roofing, and siding.

PVC Resin K-value 67

PVC Resin K-value 67 is a polymer material with a K-value of 67, measuring its molecular weight and viscosity. It is used in plastic products like pipes, tubes, sheets, and profiles and in the construction industry for roofing, flooring, and insulation. This type has good tensile strength, durability, and resistance to chemicals.

PVC Resin Paste Grade

It is a type of PVC used in making pastes or suspensions in water or other solvents. Because of its smooth mixing property with water in the paste form is widely utilized in the coating, adhesives, and sealants production.

High-Density Polythene (HDPE)

High-density Polyethylene (HDPE) has a high density and is more rigid and durable than LDPE. It is applicable in making pipes, plastic bottles, and containers because of its stiffness, strength, and chemical and moisture resistance.

High Impact Polystyrene (HIPS)

High Impact Polystyrene (HIPS) is a cost-effective and tough plastic that can be easily fabricated and thermoformed. It is commonly used in plastic toys, electronics, appliances, packaging materials, etc.

Low-Density Polythene (LDPE)

Low-density polyethylene (LDPE) offers more flexibility than other polyethylene types. Thus, it is suitable for manufacturing packaging films, plastic bags, and agricultural films.

PET (Polyethylene Terephthalate)

Polyethylene Terephthalate (PET) is a transparent, durable, lightweight, and moisture-resistant plastic used in bottle production for food, beverages, and personal care products. It is also suitable in synthetic fibers, packaging film, and much more.

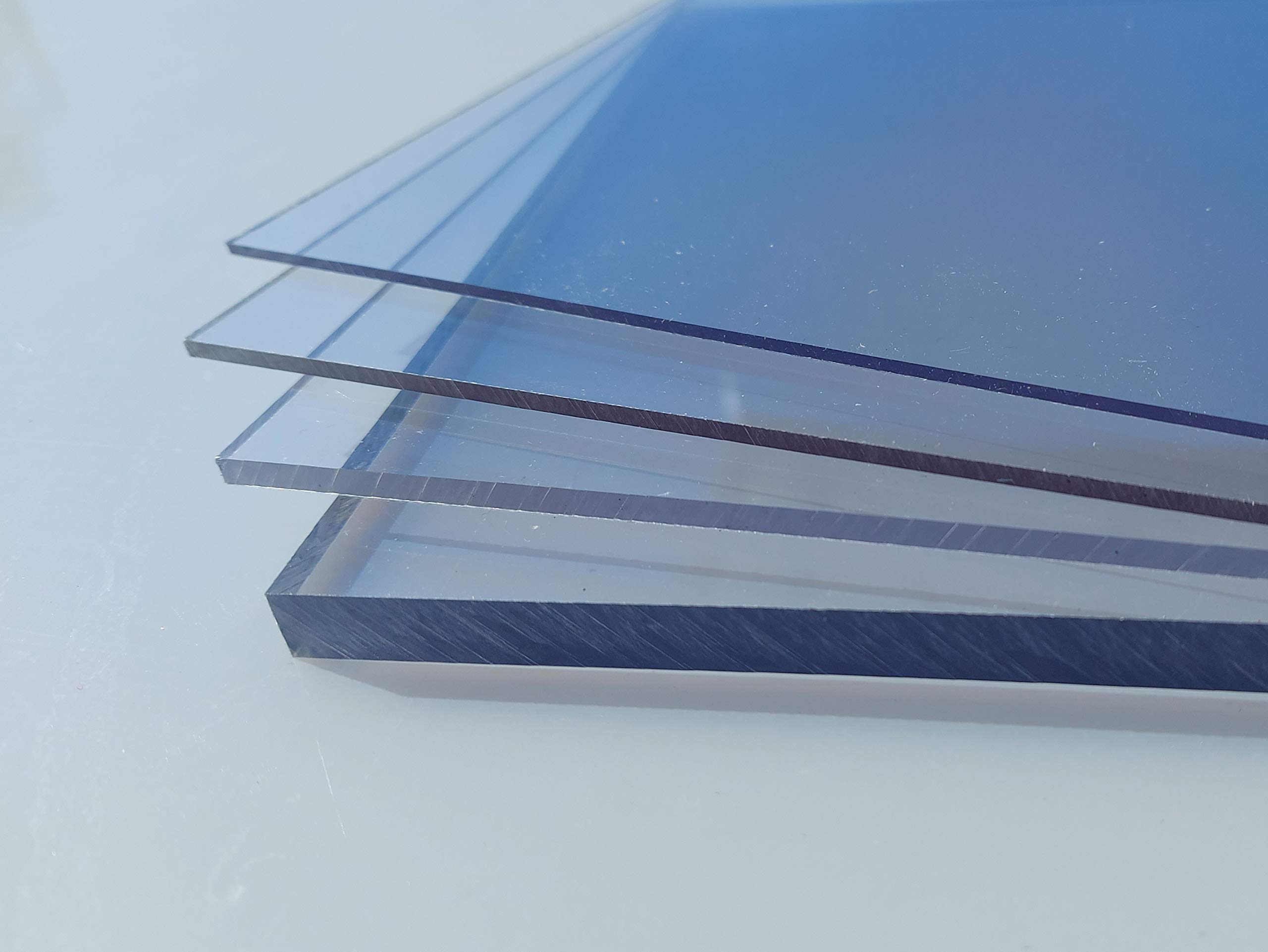

GPPS (General Purpose Polystyrene)

General Purpose Polystyrene (GPPS) is a hard, transparent, brittle plastic and easy to process. It is used in food and beverage packaging, disposable cutlery, CD jewel cases, and toys. It possesses excellent dimensional stability, good electrical insulation properties, and resistance to chemicals and moisture.

Contact Us

Get In Touch

raj.kamdar@ymail.com

mishapetrochemical@yahoo.com

raj.kamdar@mishapetrochemical.com

Phone

Mobile No : +919833138664 / +919004838664

Office Tel No : +91 22-50023747 /

+91 22-50023731 / +91 22-50023742

Misha Petrochemical

We Work, 5th Floor, Spectrum Towers,

New Link Road, Malad West, Mumbai - 400064,

Maharashtra, India

Leave A Message

All Rights Reserved